From field to dish!

On the left side are the ripe coffees which is livelihood of thousands of rural families in the Highland Vietnam. On the right is an example of a multi-billion dollar export market. How far apart are those two images?

On the left side are the ripe coffees which is livelihood of thousands of rural families in the Highland Vietnam. On the right is an example of a multi-billion dollar export market. How far apart are those two images?

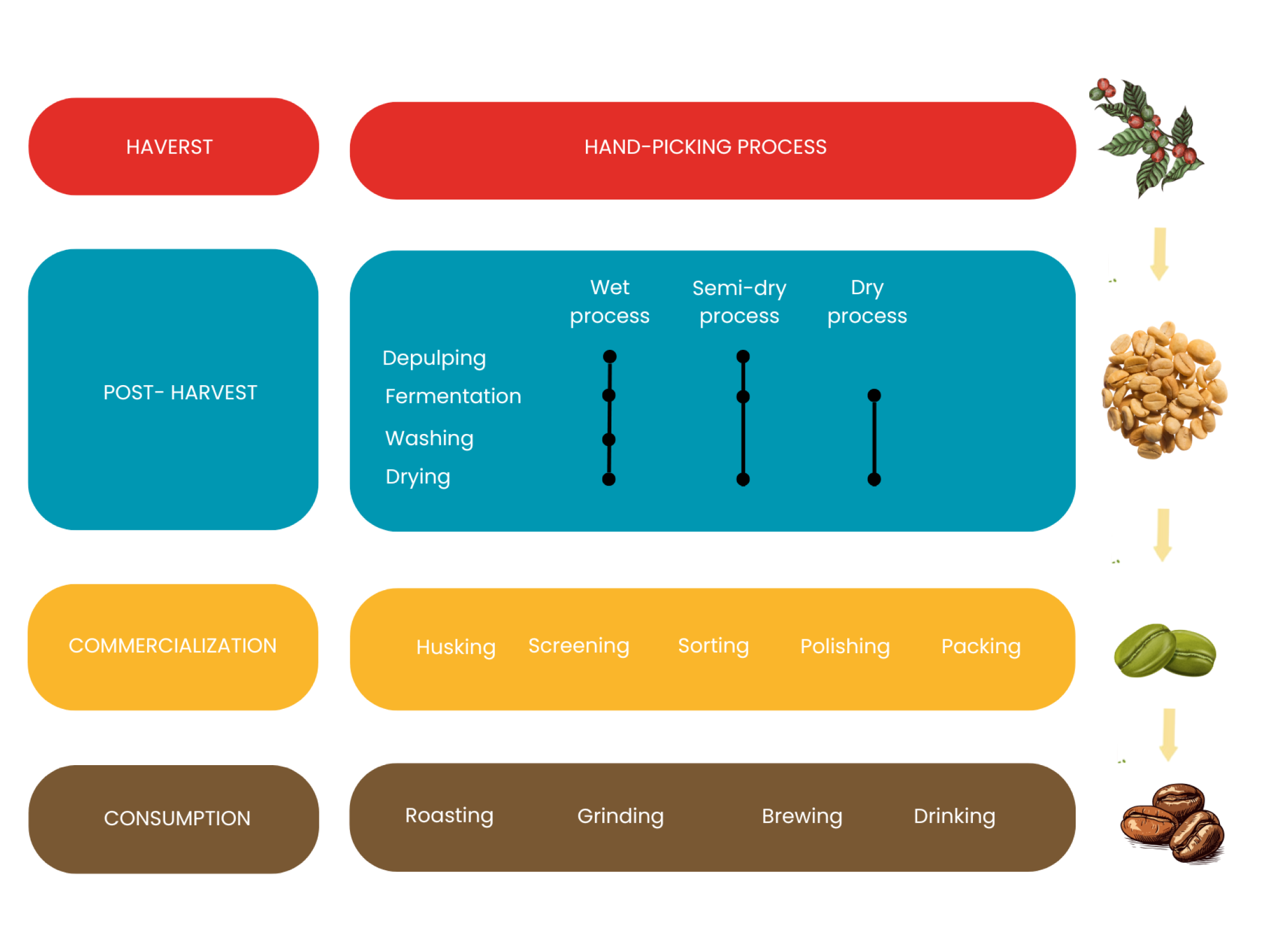

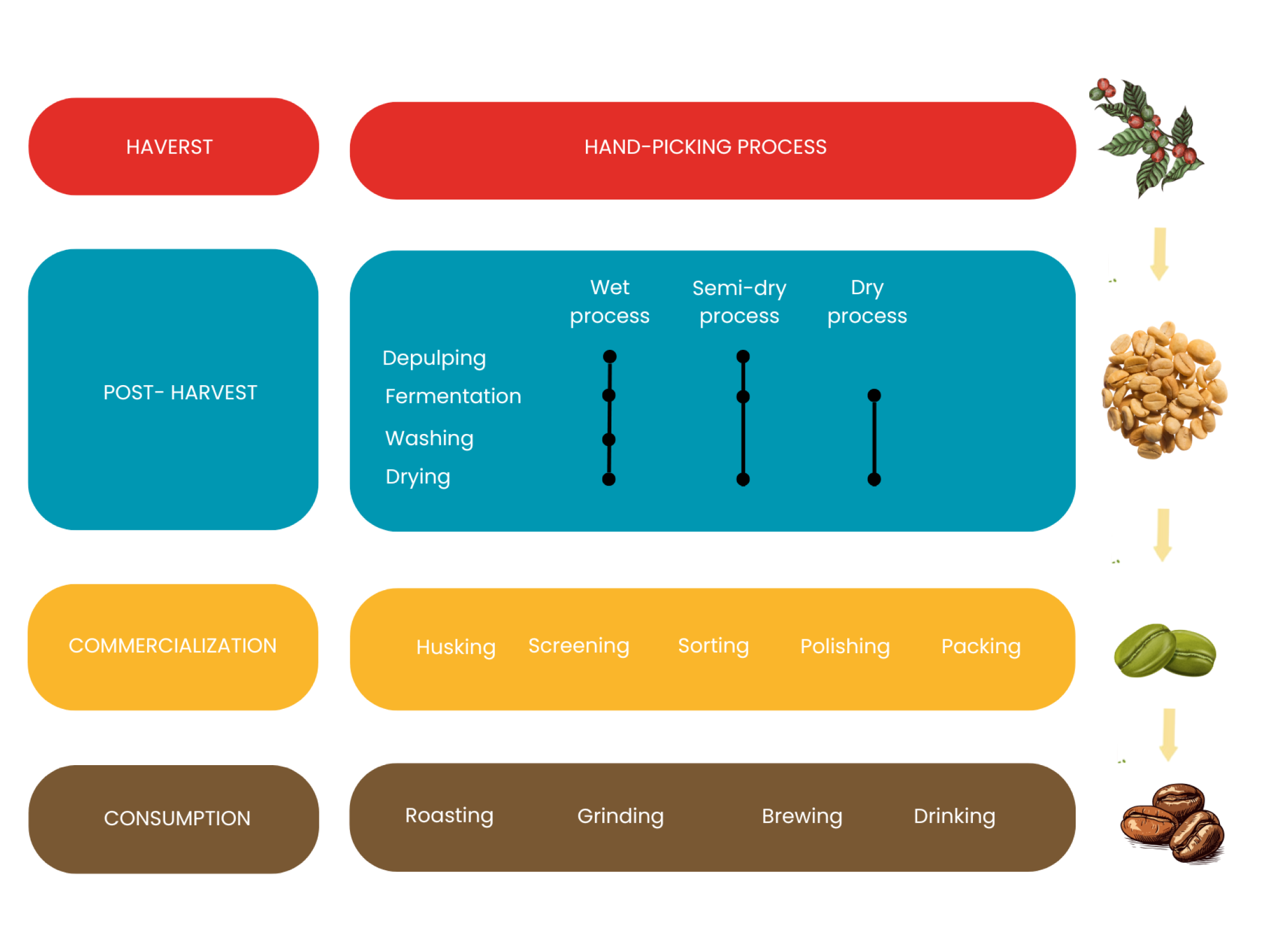

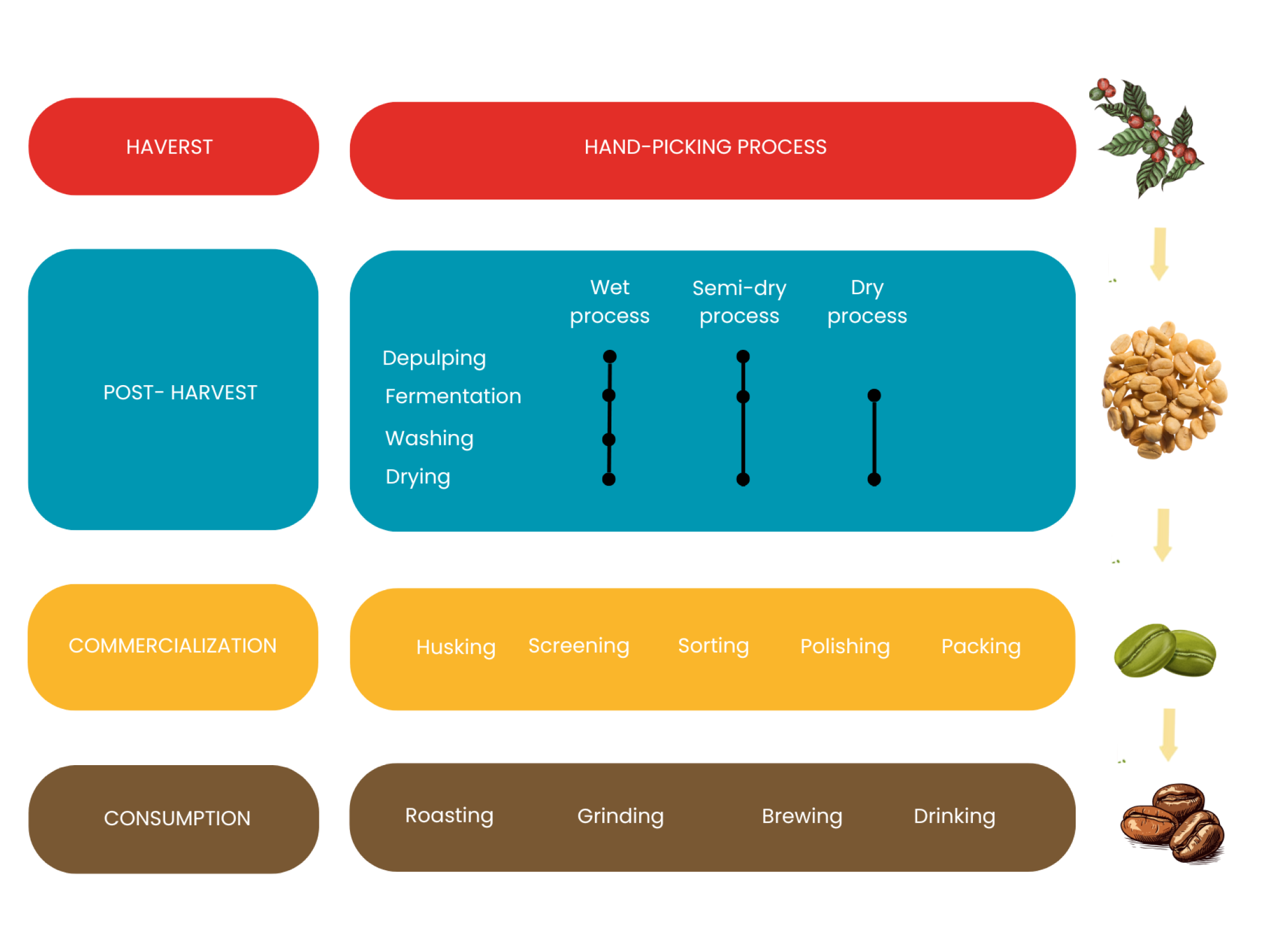

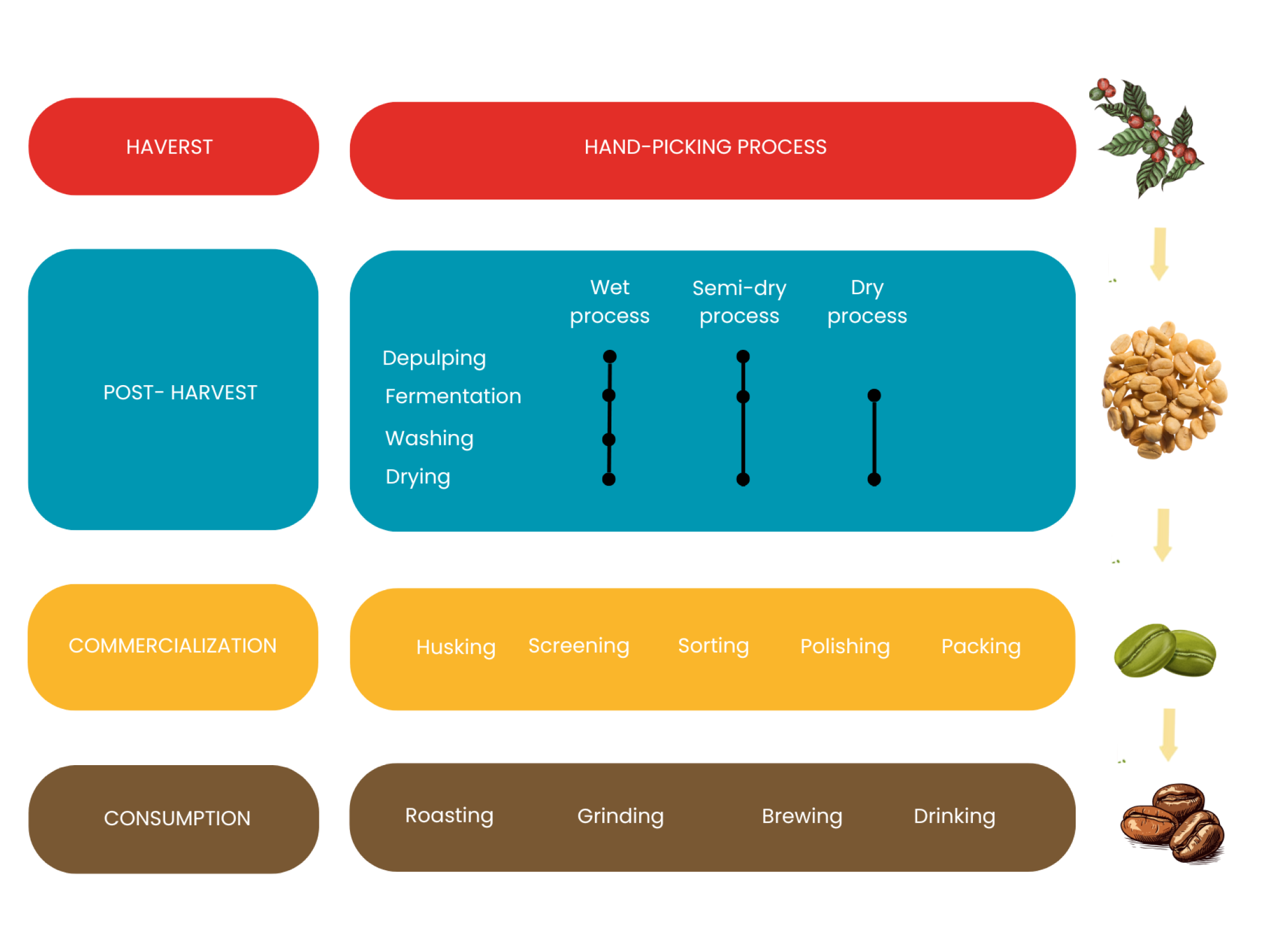

Harvesting: The Journey of Robusta

Robusta coffee found its home in Vietnam in the 19th century, introduced by the French during the colonial era. After initial trials, it thrived in the Central Highlands, where the rich basalt soil and temperate climate provided the perfect conditions for growth.

Every harvest season, from November to February, is filled with hope, as it brings dreams of a good year ahead. Farmers—many from ethnic minority communities—hand-pick the ripest cherries, carefully filling their baskets. The sight of full baskets and the sound of laughter in the fields tell the story of the deep bond between people and their land. This process not only preserves the coffee’s bold flavor and unique aroma but also continues a legacy rooted in tradition and care.

Post-Harvest: Crafting Quality

Once harvested, the coffee cherries begin their transformation. They go through steps like removing the pulp, fermenting, washing, and drying, depending on the chosen process: the wet, semi-dry, or dry process. Each gives the beans a unique character.

In Vietnam, the drying process is the most popular. Under the warm sun of Vietnam, the beans dry slowly, holding onto the flavor and care they received from the farmers. Each step is simple but filled with dedication.

Commercialization: Refining Excellence

Over 90% of Vietnam’s coffee exports are green coffee beans, known for their bold flavors and reliable quality—perfect for creating exceptional blends.

The preparation process involves:

Vietnam is also advancing in value-added processing, developing unique roast profiles and promoting Vietnamese-style brewing methods, showcasing its coffee’s full potential to the world.

Consumption: A Taste of Vietnam

When I talk to my international friends, they’re often surprised to learn that Vietnam is the second-largest exporter of Robusta coffee in the world. It’s exciting to think that in every cup of coffee you drink, there’s a good chance it contains a blend of Vietnamese beans. Whether brewed as a strong espresso or a classic Vietnamese drip coffee, each sip carries the bold, earthy flavors of the Central Highlands, connecting you to the heart of Vietnam’s coffee culture.

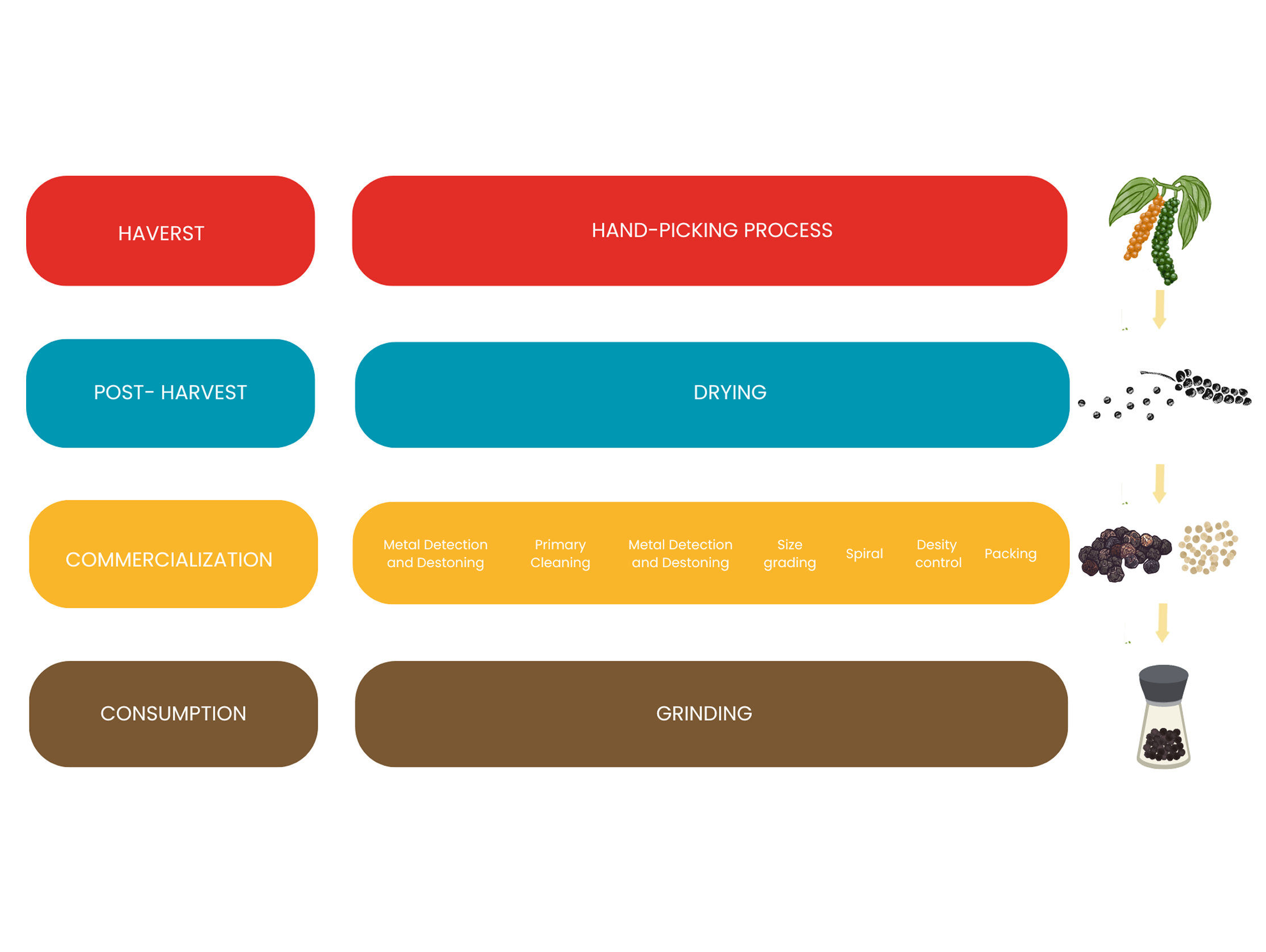

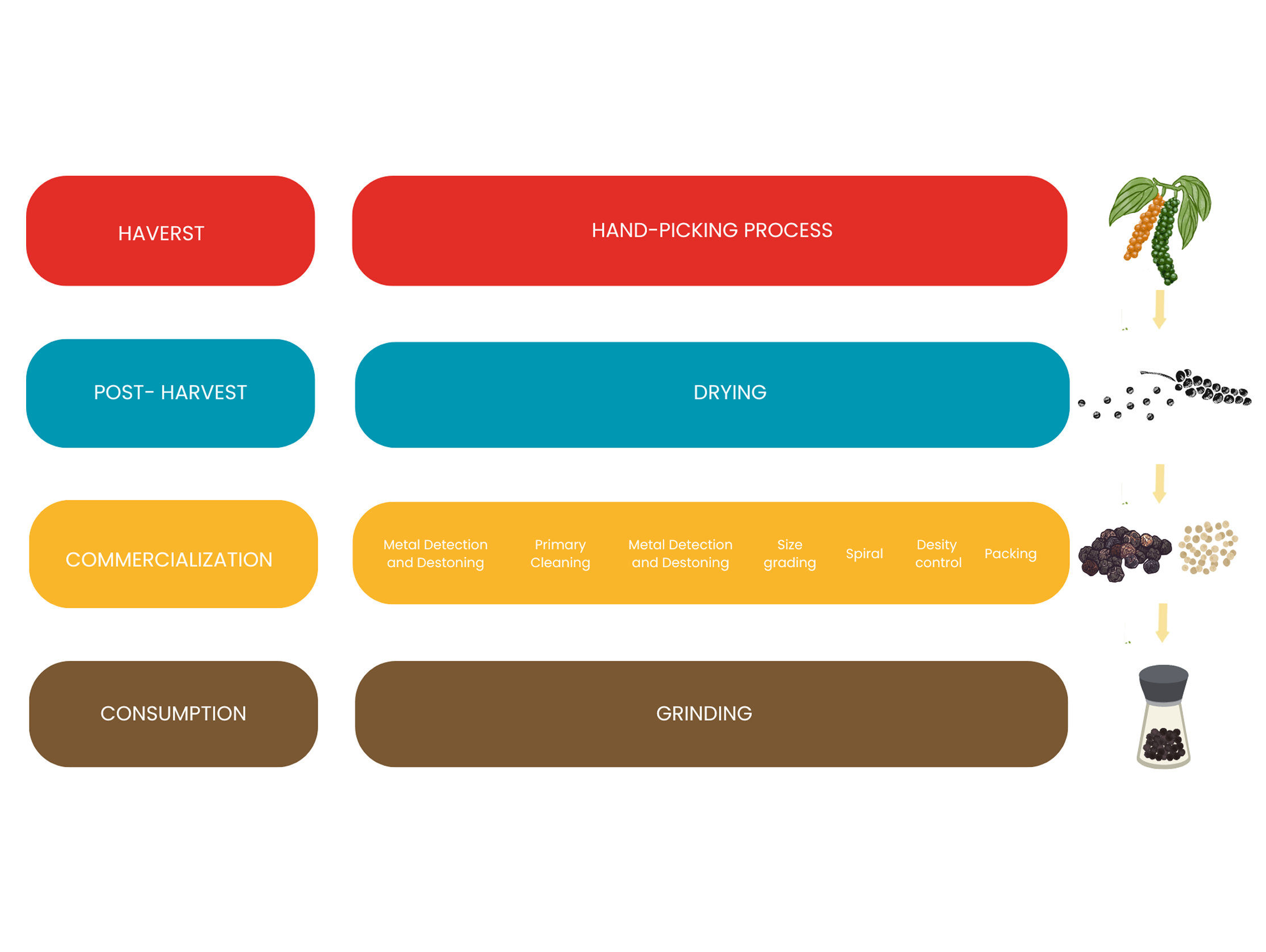

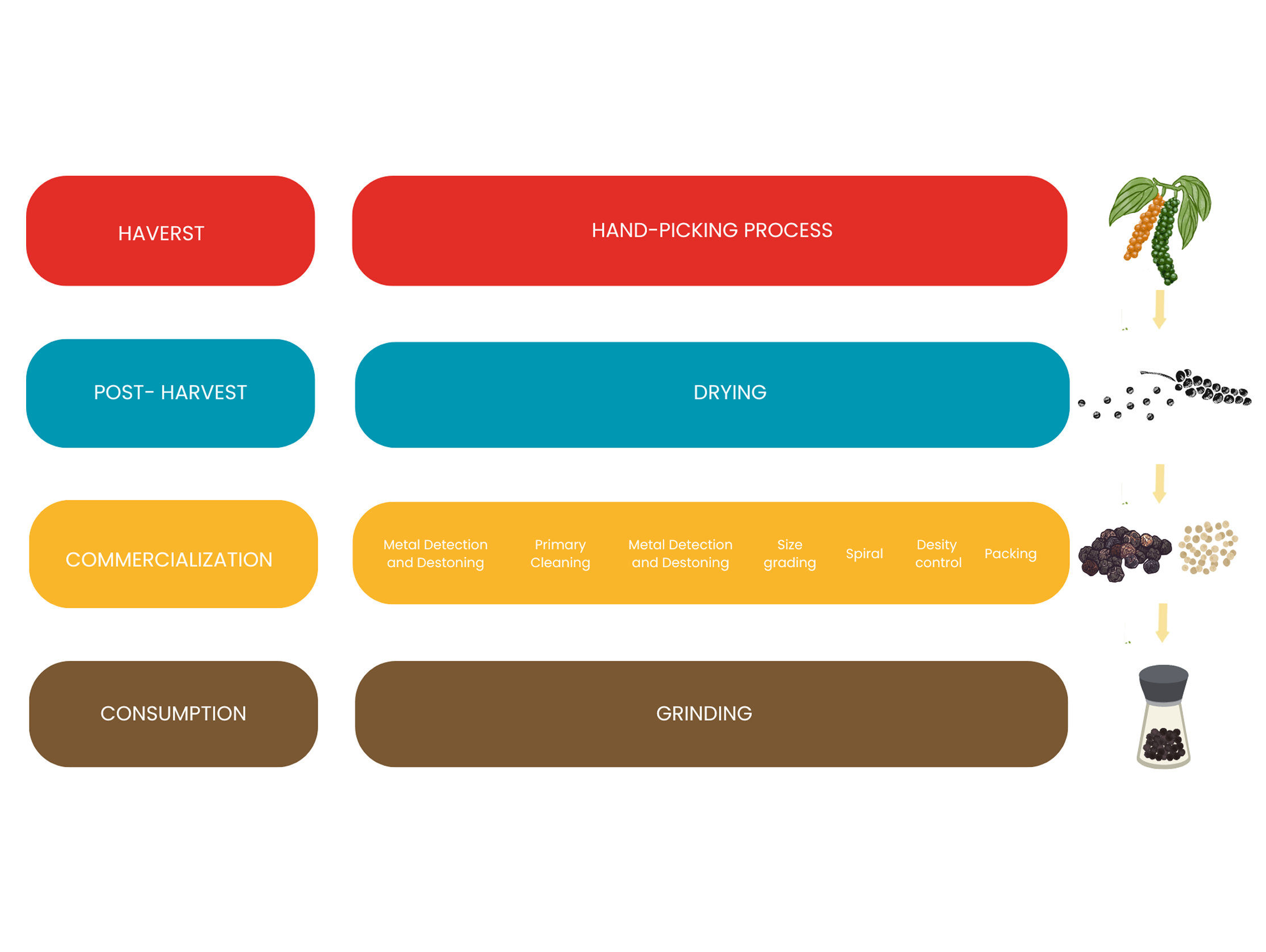

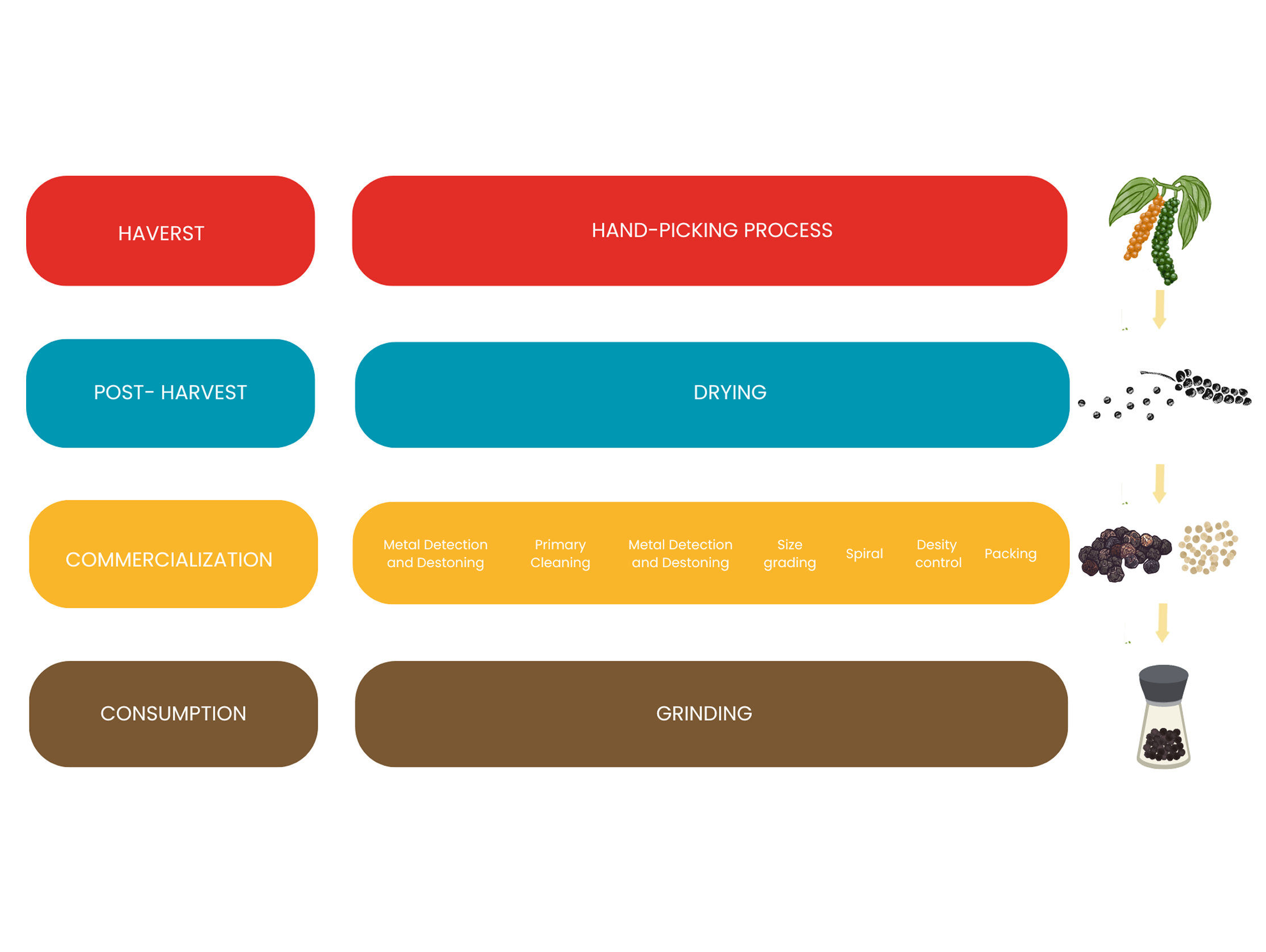

In the pepper-growing regions of Bình Phước, Đồng Nai, and Đắk Lắk, it takes 3 to 4 years for a pepper vine to bear fruit. The plant is challenging to grow, requiring careful nurturing and the right conditions.

During harvest, farmers hand-pick each ripe cluster with care, ensuring quality from the start. This labor-intensive process is more than work—it’s a tradition deeply rooted in the land and the lives of those who cultivate it.

Once harvested, the peppercorns undergo traditional yet meticulous steps to maintain their quality. After washing, they are spread out under the sun to dry slowly, a process that enhances their rich, spicy aroma.

In Vietnam, sun-drying is a time-honored method, where the warm climate and patient farmers ensure every peppercorn retains its bold flavor. Simple but filled with dedication, thi transforms basically transforms peppercorns into the high-quality spice that Vietnam is known for.

From raw peppercorns to a premium product, every step in Vietnam’s pepper processing reflects precision and care:

Through this detailed process, Vietnam ensures its black pepper stands out globally, trusted for its consistency and bold flavor.

Pepper may seem like a simple spice, but its impact on flavors is anything but ordinary. A pinch of Vietnamese pepper can elevate a humble soup or a gourmet steak, bringing out layers of depth and warmth.

The pepper on your plate carries with it the tropical sun, the care of farmers, and the rich heritage of Vietnam. Whether used in everyday cooking or fine dining, Vietnamese pepper adds a spark to every dish, reminding us how the simplest ingredients can create unforgettable moments.

In the misty highlands of Yên Bái, where cinnamon trees thrive, skilled farmers hand-harvest only the finest cassia bark. Introduced to the world by the French in the 19th century, Vietnamese cassia quickly gained recognition for its rich aroma and high essential oil content. The selection process focuses on quality: bark thickness 2.5–3mm, free of mold or blemishes, ensuring a premium product.

The journey of cassia continues step by step:

Storage: Stored in sealed bags on pallets, following strict spacing standards to maintain quality.

From bark to export-ready cassia, each step is carefully done:

Consumption: A Global Spice

Both Ceylon cinnamon from Sri Lanka and Cassia cinnamon from Vietnam have unique qualities. While Ceylon is known for its delicate flavor, Vietnamese cassia is prized for its bold, sweet-spicy profile and high essential oil content. This makes cassia a versatile choice, widely used in baking, beverages, and savory dishes across the globe.

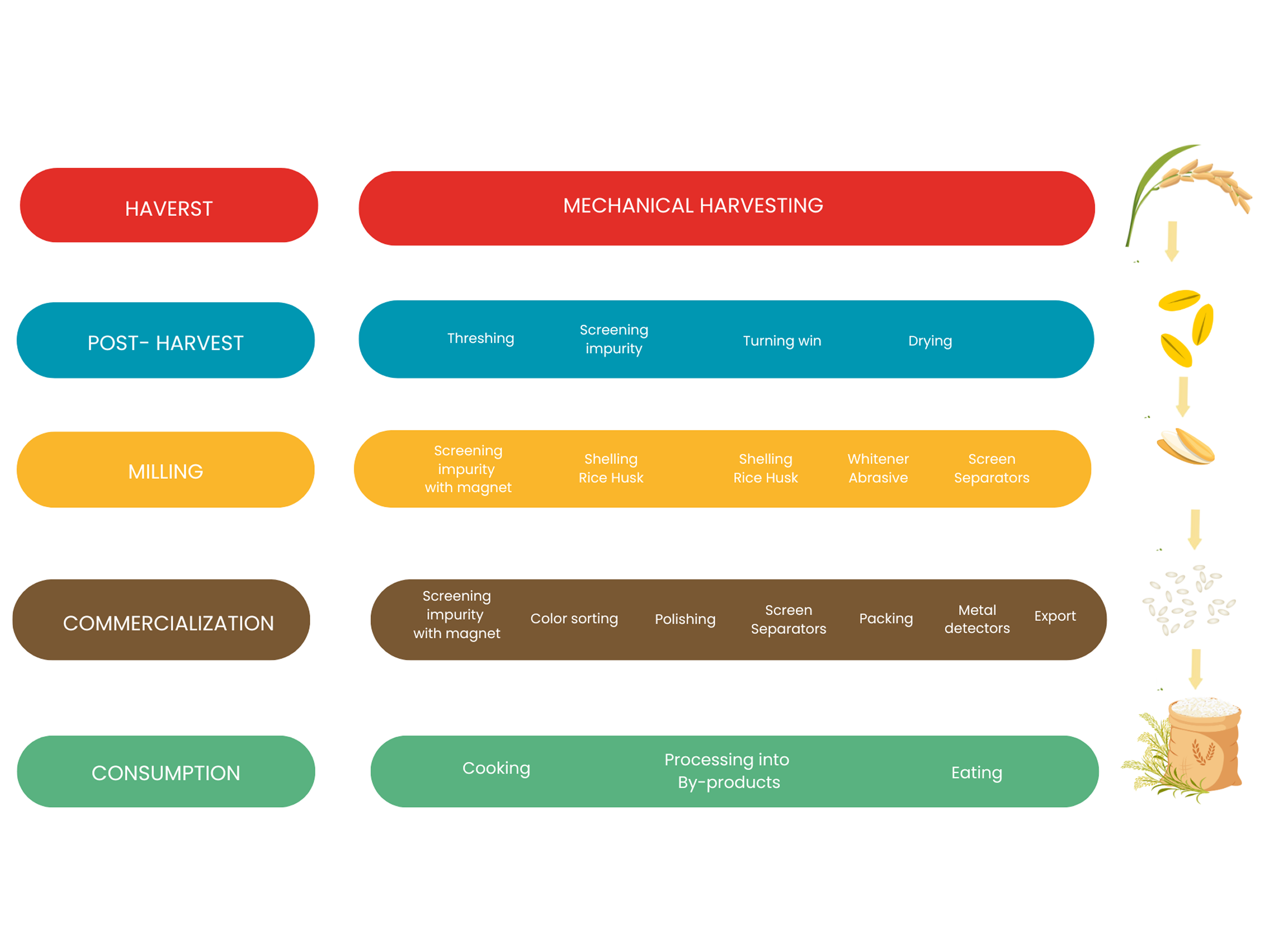

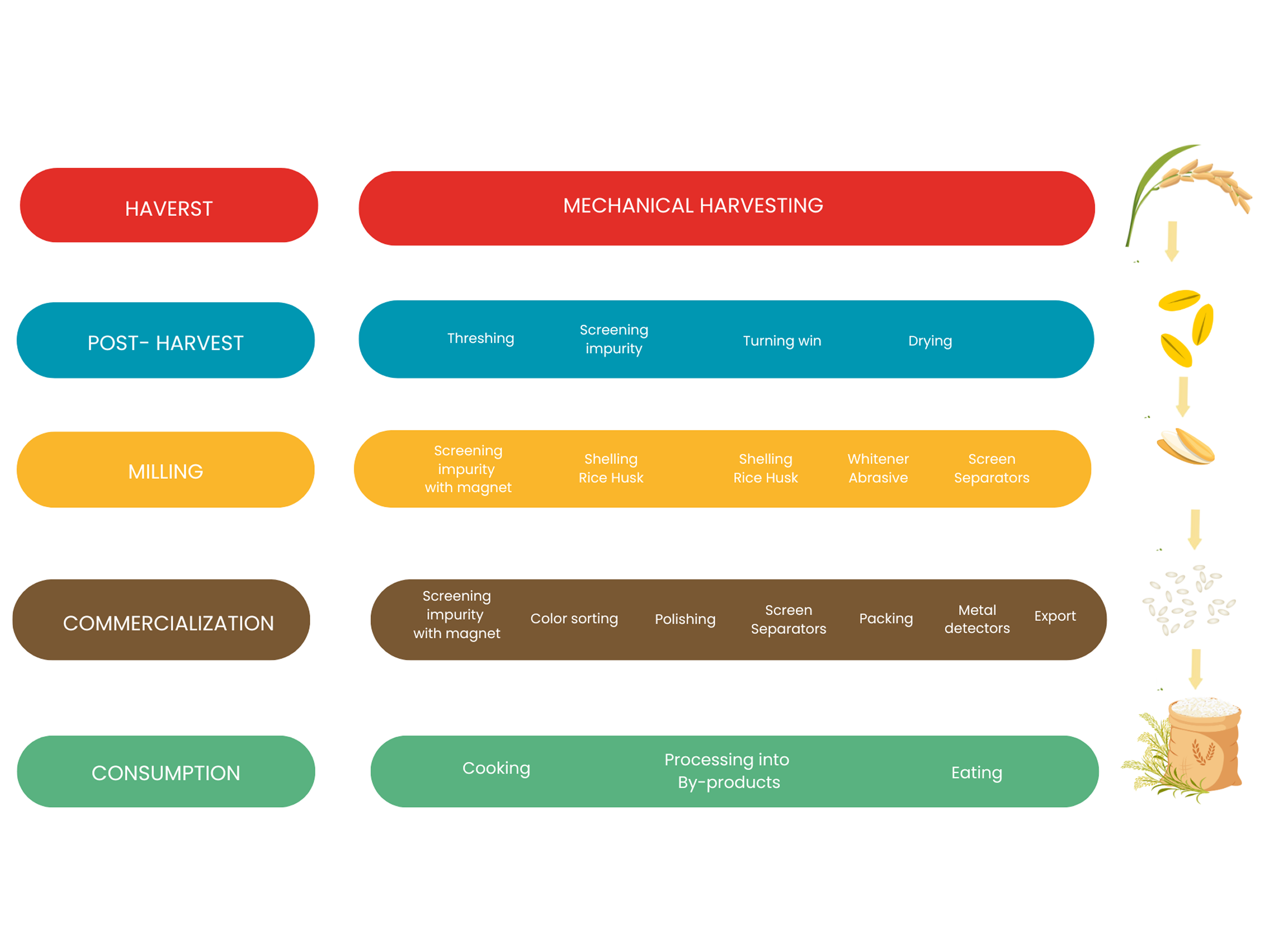

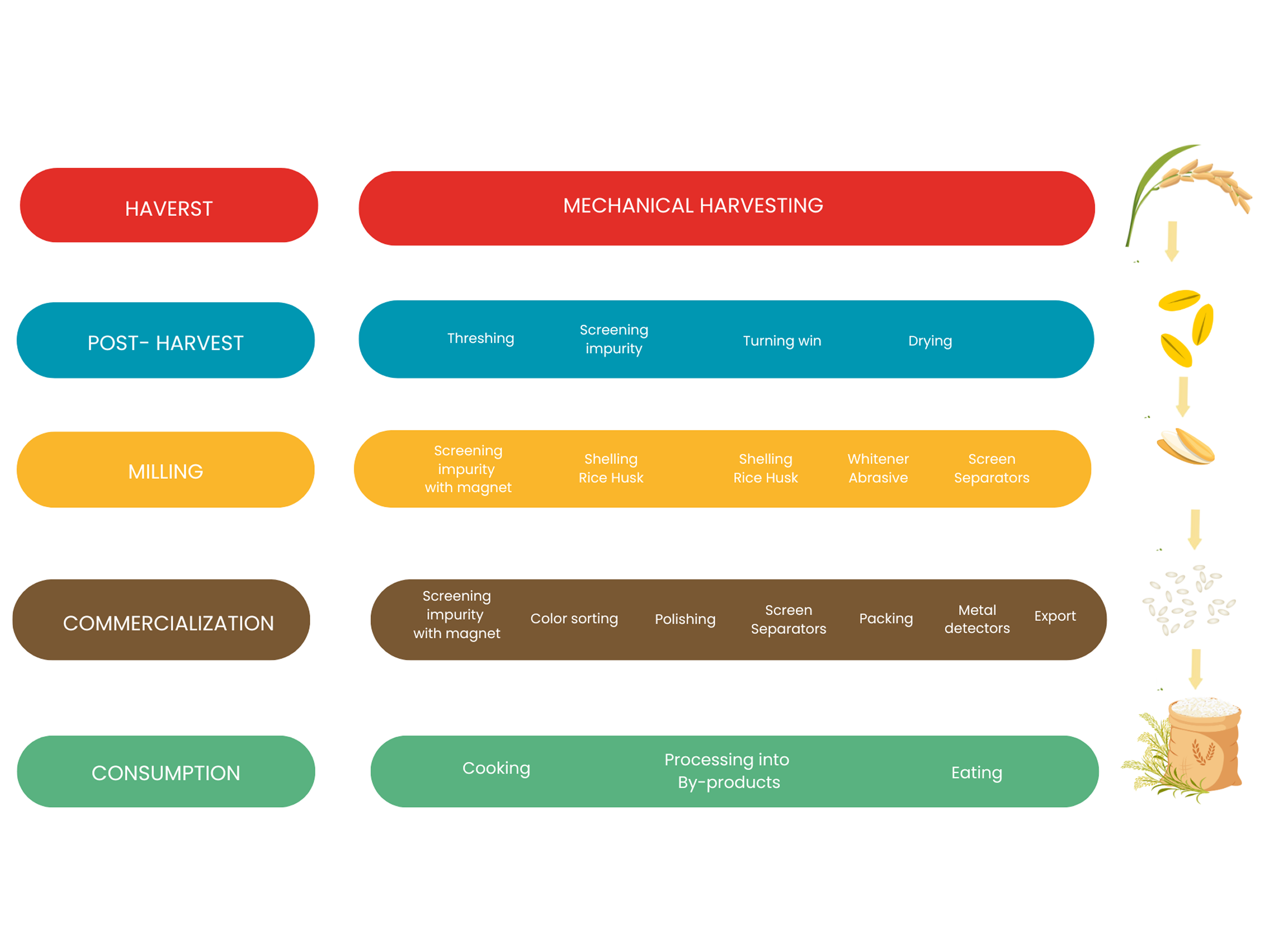

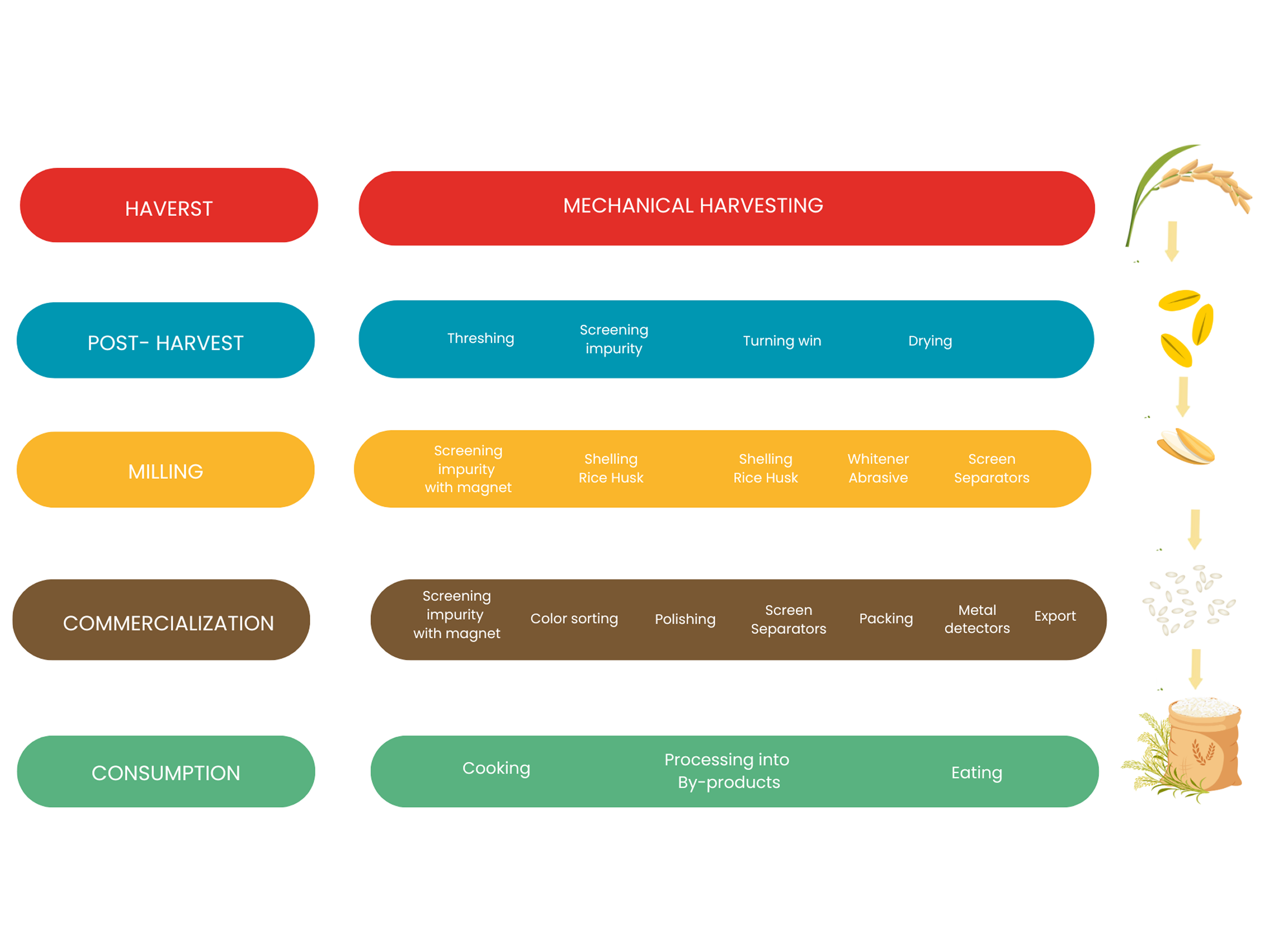

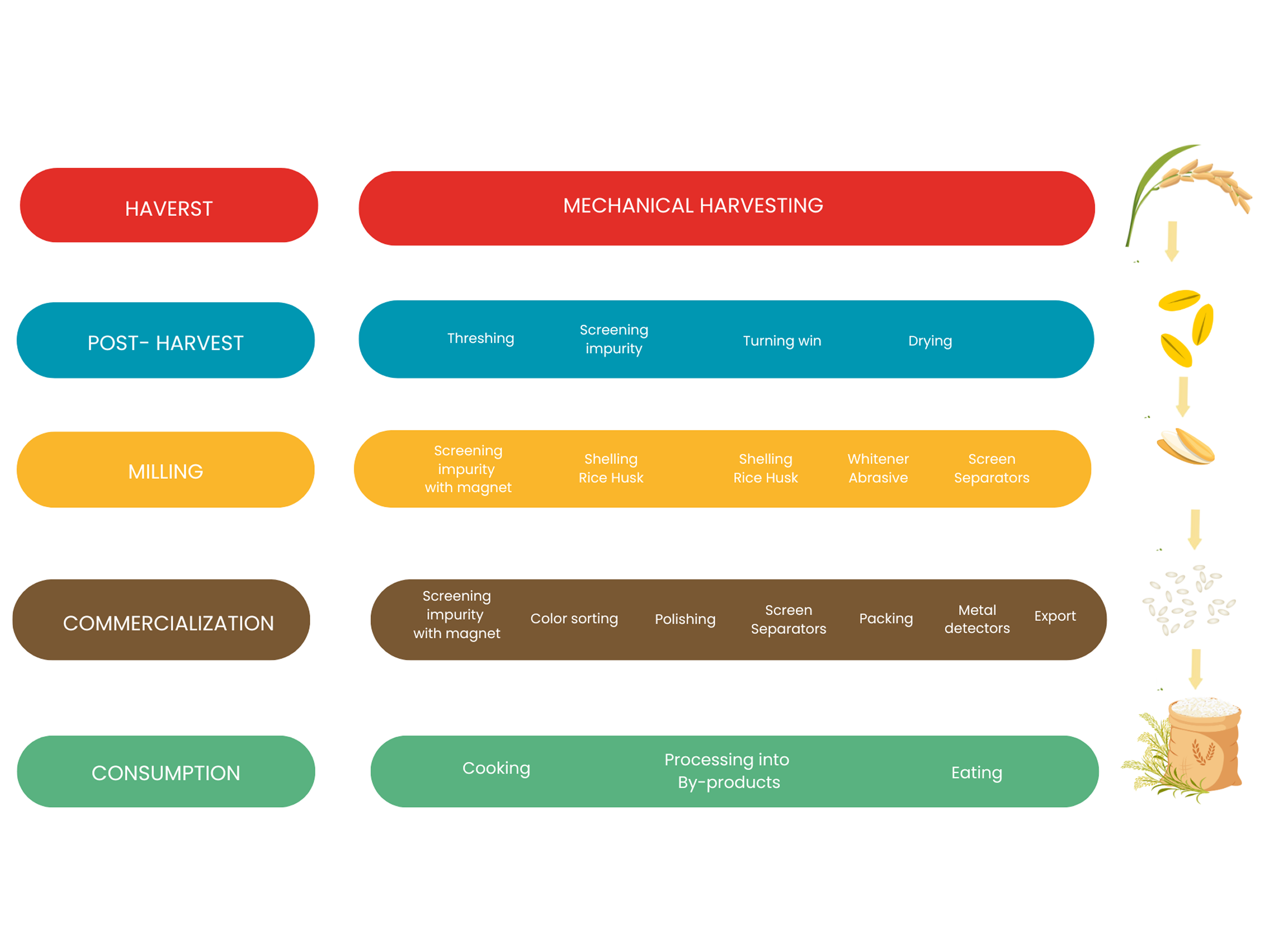

Harvesting: The Rhythm of Rice Seasons

In Vietnam, rice is harvested across three seasons: Winter-Spring, Summer-Autumn, and Autumn-Winter. From December to March, the Winter-Spring season kicks off, followed by Summer-Autumn and finally Autumn-Winter, marking the end of the year’s cycle.

Modern machinery has made the process faster, but rice farming still holds deep roots in tradition. Many varieties now grow in about 90 days, especially in the Summer-Autumn and Autumn-Winter seasons, ensuring both quality and efficiency.

The harvest is a time of unity and celebration, where farmers, deeply connected to the land, bring forth the golden grains that will nourish the world for generations to come.

Post-Harvest: Shaping the Essence of Rice

After harvesting, the paddy rice begins its journey to becoming dry rice, with several key steps to ensure quality. The rice is carefully screened to remove impurities like dust, rice husks, small stones, and low-quality grains.

Next, the rice is cleaned using air flow through a turning fan to reduce moisture and remove light impurities. The rice is then dried to perfection and stored in moisture-resistant silos, protecting it from insects and spoilage.

Each step in the post-harvest process plays a crucial role in shaping the rice’s quality, ensuring it’s ready for the next steps with the utmost care from the farmers.

Milling: The Journey to Purity

Once dried, the rice begins its milling journey. First, it’s screened again to remove any remaining impurities like metal pieces, dust, and rice husks.

The husk is removed to reveal brown rice, which is processed through abrasive whiteners to remove the bran layer and turn it into white rice. This meticulous process separates broken grains from whole ones, ensuring only the best rice reaches the market.

Milling can result in up to 10% of grains being broken or damaged, which is why careful separation is essential for high-quality rice!

Commercialization: Perfecting Rice for the World

After milling, the journey to premium rice begins. Magnets remove any remaining impurities, followed by color sorting machines that detect and remove damaged or chalky kernels.

The rice is polished to a glossy finish, making it as visually appealing as it is delicious. Finally, it’s carefully packaged in materials like PP, PE, or BOPP, which preserve quality and freshness.

Rice packaged with vacuum sealing can last up to 50% longer!

Metal detection ensures that only the safest rice reaches your table, guaranteeing the essence of Vietnam’s finest rice is ready for export.

Consumption: The Heart of Every Meal

Rice completes its journey on our plates, transforming into fragrant bowls of steamed rice, creamy porridge, or a myriad of other dishes. Rice is the foundation of beloved by-products like rice vermicelli (bún), pho noodles, rice paper (bánh tráng), rice crackers, and even rice wine!

As a staple in daily meals, rice transcends cultures, connecting people through its versatility and nourishment. Rice provides over 20% of the world’s caloric intake, making it a true hero of global cuisine!

Harvesting: A Symphony of Dedication and Nature

Under the golden sun, where the salty breeze whispers through the leaves, begins the journey of desiccated coconut. Farmers, often working barefoot in the damp soil, climb coconut trees that have grown for at least three years to collect mature fruits—coconuts that are at least 10 months old. Each tree is more than a plant; it’s a legacy passed down through generations, a source of both livelihood and pride.

Did you know? A single coconut tree can produce up to 75 coconuts per year, and each nut carries not just sustenance but a treasure trove of possibilities—from oil to milk to the finely grated desiccated coconut.

After careful hand-picking, every coconut is meticulously inspected. The outer shell must remain intact, free from cracks or mold. The flesh inside must be pristine, white, and fragrant—a testament to its freshness.

Farmers who supply coconuts for desiccation often follow sustainable agricultural practices, ensuring that each harvest not only nurtures the community but also protects the earth. It’s a process that reflects a simple truth: the best products begin with care, patience, and respect for the land.

The journey continues as the rugged exterior of the coconut gives way to its pure, creamy essence—its meat. Once harvested, the coconuts undergo meticulous processing, where every step is guided by precision and care.

Husk removal is the first challenge, as the tough, fibrous outer layer is stripped away to reveal the hard shell beneath. It’s a process requiring both strength and skill, honed over years of experience.

Did you know? The husk of the coconut isn’t just waste—it can be repurposed into coir, used for making ropes, mats, and even eco-friendly planting pots.

Afterward, the coconut shell is carefully cracked, and the meat is separated. This is the heart of the coconut, rich in flavor and nutrients, and the foundation for desiccated coconut. Each piece is inspected to ensure it’s free from impurities, guaranteeing the highest quality for the next stage of production.

In every coconut, there’s a story of resilience—of farmers, nature, and a process that transforms raw potential into something extraordinary.

The process of turning fresh coconut meat into desiccated coconut begins with simple, careful steps.

The coconut meat is washed to remove impurities and soaked in a solution to maintain its freshness and appearance. Fun Fact: Soaking helps retain the coconut’s natural color and sweetness, ensuring that each piece is as vibrant as it is flavorful.

Shredding the meat and heat-treating it ensures safety, while drying it to just the right moisture level takes patience and precision.

Once dried, the coconut is sieved into grades based on size, and metal detectors catch any potential impurities. It’s an ongoing effort to ensure that only the best coconut reaches your hands, with nothing left to chance.

Every step reflects the care and attention required to create something pure, the kind of dedication that is rarely seen, but always felt in every bite.

Packing & Export:

Once weighed (25kg or 7kg), the desiccated coconut is sealed in packaging that locks in freshness. The layers of PE, kraft, and PP protect it from moisture, ensuring the coconut arrives at its best.

Quality Control:

A final metal scan ensures purity, with each package labeled for full transparency. Even the smallest impurity is caught before it leaves the facility.

Storage & Export:

Stored at optimal conditions, the desiccated coconut is then sent worldwide, ensuring every bite reflects the care it took to create.

Desiccated coconut is a versatile ingredient with a wide range of applications. It’s the secret ingredient in your favorite cakes, cookies, and even coconut truffles! It also enriches savory dishes like curries and soups, while topping off your breakfast with granola bars and smoothies.

When it comes to beverages, desiccated coconut is blended into coconut milk, shakes, and tropical drinks, contributing a creamy texture that elevates the drink experience.

Did you know? Desiccated coconut is also found in pastries, where its natural sweetness perfectly balances rich flavors. Beyond the kitchen, it’s used in skincare products for its moisturizing properties and health supplements for a nutritious boost.

Between the coffee farmers in Vietnam’s red basalt soil and any CEO in the world, there are at most six degrees of connection. But what binds them together is an unyielding effort to build teams and technology. Between the vast coffee highlands and the billion-dollar beverage market, there is AGRESO.